|

|

1610 Auto feeding Co2 laser cutting machine for fabric

Collect

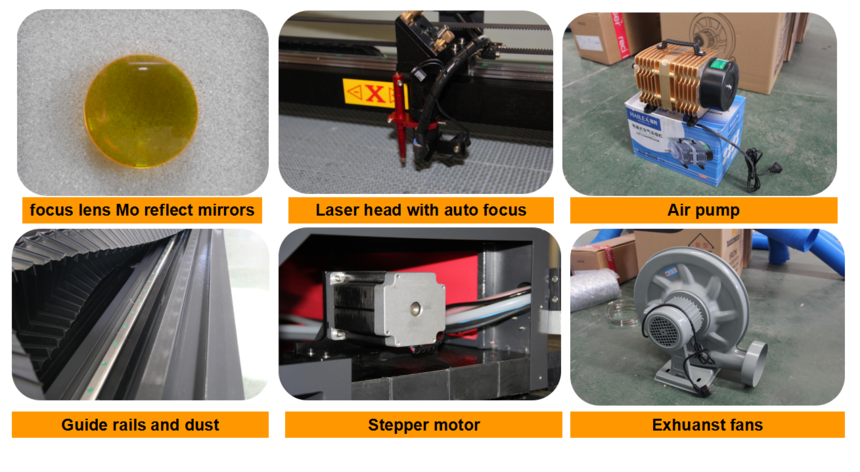

1610 Auto feeding Co2 laser cutting machine for fabriccnc clothing laser cutting machine 1610 fabric cut laser with auto feeding system 1.Double heads with high efficiency and effectiveness work simultaneously. 2.The auto-feeding function is specially designed for piece goods, such as cloth, fabric,Towel, leather, jeans, knit article, embroidery, etc. 3.Widely applied in clothes embroidery industries. The laser cutter with auto feeding system fixed with a selective rolling & automatic feeding system, which make the whole cloth processing steps finish in one time. The laser cutter engraver for sale is suitable for engraving and cutting on very long work piece, such as one roller of cloth,fabric, leather, garment. This fabric laser cutter especially applied in fabric and garments industry. Main Features1. Adopt "Automatic Feeding and Rolling System" to make the whole cloth processing steps finish one time, so the fabric laser cutter is suitable for engraving and cutting on very long work piece, such as one roller of cloth, fabric, leather, garment. Machine Feature Auto feeding tableThe auto-feeding function is specially designed for piece goods, such as cloth, fabric,towel, leather, jeans, knit article, embroidery, etc. It's so practical. Widely applied in clothes industries. Double headsDouble heads with high efficency and effetciveness work simultaneously. Time saving parts can cut kinds of piece goods, such as cloth, fabric,Towel, leather, jeans, knit article, embroidery, etc. Control panelThe work table is controlled by Ruida works & 8 software. When to move, and how far to move, all of this data can be set up on the digital panel. Laser sourceSupplies power for the laser tube with high quality. Rolling systemThe piece goods in rolls are put on the rolling syste,The table can move forward every time you finish cutting, and the rolling system can rotate the goods when working, in this way, the goods can be processed effectively. Control systemRuida control card, driving system(x-axis, y-axis, z-axis), power supply, air switch, intelligent no-arc ac contactor included.

textile leather fabric co2 laser cutting machine is mainly used for cutting fabric, especially fabric rolls. Our cloth cutting machine with auto feeding system, no need you to put cloth on the machine bed by manual.This laser cutting machine also can cut some other non metal materials, such as acrylic, wood, leather, fabric, rubber, plastic, paper, MDF, PVC, ABS etc. This 1610 laser machine also suit for engrave cut almost all nonmetal material include wood, MDF,acrylic, plywood, etc. But as auto feed worktable not with electric up down function, user can only manual adjust Z axis on laser head, it support the max material thickness 30mm.

Package (1) Inner: plastic stretch film and white foam. (2) Middle: small pieces of wood and screws. (3)outside: standard export wooden case. So,the laser machine will send to you safely. FAQ 1. Q: How long does it take to learn the laser? A: The software is easy to learn with teaching video, also we can help you to learn the laser online. Usually it will take a few hours to operate the laser ,But it will take a bit of trial and error to learn what speed and power settings to use with different materials. So we include a comprehensive guide with your system that has recommended speed and power settings for various materials with which you will be working. 2. Q: Will the laser machine be safe during transport? A: (1) Inner: plastic stretch film and white foam. (2)Middle: small pieces of wood and screws. (3)outside: standard export wooden case. So,the laser machine will send to you safely. In case the machine was damaged , please contact us ,We will process the replacement as soon as possible to ensure that it arrives in time . 3. Q: What should I do when something goes wrong with the laser? A: We offer a two-year warranty. In warranty, we will provide the broken items free of charge. Beyond the warranty period, we still provide maintenance service. 4. Q: How deep can it engrave into metal? 5. A: All metals can be engraved into with some depth; However, some metals are more amenable to depth engraving. Softer aluminum material will engrave with depth with only a few passes. We provide samples testing. You can send your samples to us, then we will make test by your wanted machine. |